Xionggu Electrical is a professional manufacturer of welding equipment. We provide one stop solutions for pipeline welding. Founded in 1992, Xionggu has become a well known welding equipment R&D and manufacturer in China. We have participated in almost all pipeline construction projects in China and have strong footprints in Middle East, Africa ,West and South Asia through the past 33 years of development.

Xionggu owns 200 patents and have an R & D institute and a special test lab for welding equipment. Our operations are strictly implemented in accordance with ISO9001, ISO14001 and ISO45001. Arc droplets accurate control, arc welding seam tracking and Data cloud management system are the three core technologies we employed in our welding products, which put us standing out of our competitors. Xionggu recognize bringing long term value to customers is important to the sustainability of the business, so we have a strong technical team actively being in customers' construction place providing on-site service.

Xionggu pipeline automatic welding machines are accredited with Scientific and Technical Achievements by Petroleum Engineering Association. Xionggu Electrical is also a member of International Pipe Line & Offshore Contractors Association (IPLOCA).

We strive to keep the continuous innovation with the aim of positioning ourselves as one of the leading global welding machine companies.

Since its establishment in 1992, Xionggu has gone through four milestone development phases:

-The Foundation Period (1992–1999): Overcoming hardships to build a solid groundwork.

-The Growth Period (2000–2012): Advancing steadily with a focus on progress.

-The Transformation Period (2013–2016): Breaking through with innovation.

-The Leap Forward Period (2017–Present): Achieving sustained and far-reaching growth.

Through 33 years of meticulous dedication, we have accomplished three major leaps:

- From a small welding equipment workshop along the Jinjiang River to a high-tech enterprise powered by intelligent welding systems and pipeline inspection technologies.

- From traditional manufacturing to an industry exemplar with a modern governance system.

- Through persistent technological accumulation and cultural refinement, we have built core competitiveness—integrating proprietary technologies, specialized teams, and brand value—to lay the foundation for long-term success

Moving forward, all Xionggu members will uphold the core values of "Ceaseless Self-Improvement and Generous Virtue":

1. Strengthen innovation-driven strategies, establishing an agile R&D system to continuously enhance customer value with cutting-edge technologies.

2. Adhere to principled business conduct, deepening industry expertise with a craftsman's spirit to create a collaborative and win-win ecosystem.

3. Focus on green transformation, integrating AI and big data to drive sustainable development in the industry.

With unshakable (original aspiration) and relentless dedication, we will reignite the passion of "starting anew" and forge a new glorious chapter for Xionggu in the era of intelligent manufacturing!

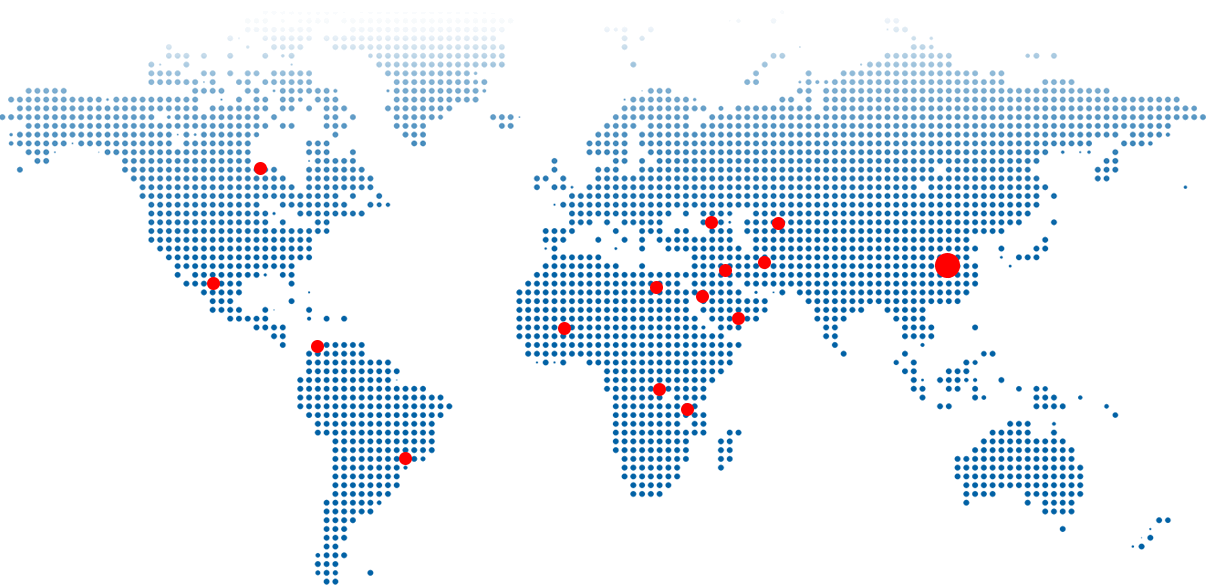

The footprint of Xionggu Company spans across the globe, with our products widely used in major pipeline engineering projects in numerous countries such as Turkmenistan, Kazakhstan, Saudi Arabia, the United Arab Emirates, Kuwait, India, Thailand, South Africa, Algeria, Cuba, and China. Especially in landmark oil and gas pipeline projects such as the China-Myanmar Pipeline, China's West-to-East Gas Pipeline Project, and Thailand's Natural Gas Line 5, Xionggu products have become the main welding equipment due to their excellent performance.

Intelligent Manufacturing: Making Welding Simpler

Providing more efficient, precise, and user-friendly welding solutions for professionals around the world.

Established overseas subsidiaries in Abu Dhabi and Saudi Arabia.

Achieved the first sales order through the MS10000 enterprise management system.

Completed the technical upgrade of oil and gas pipeline internal detectors and set a new historical high for detection service orders.

The A-391 trackless intelligent welding robot was applied in small batches in industries such as shipbuilding, marine engineering, and hydropower.

Completed the R&D of welding processes for aluminum alloys, nickel-based alloys, and other materials using the DPS-500Plus digital welding machine, successfully applied in high-end manufacturing in China.

Completed the development of the next-generation pipeline internal welding machine and successfully applied it in pipeline construction.

Developed and successfully applied the A-301 series clamp-type automatic external welding system in pipeline construction.

Completed the R&D of LT series weld seam and molten pool sensors and successfully applied them in industries such as shipbuilding.

Set up academician (expert) innovation workstation;

Set up the first overseas subsidiary in the Middle East;

A-305T argon arc external root welding equipment and process are applied to the construction of pipelines and joints in mountainous areas in batches, which improves the quality and efficiency of pipeline construction;

A-390/391 trackless intelligent welding robot was successfully developed, providing an efficient and intelligent solution for the welding of non-oil and gas pipelines;

The A-602 bridge intelligent welding robot was successfully developed, providing an efficient and intelligent solution for steel structure bridge welding;

A-610 double-gun external welding and gasketing small pipe high-efficiency welding equipment and process have been successfully applied to the construction of marine pipeline engineering;

MI series flux leakage detector/DI series deformation detector is used for pipeline testing in batches, and has successfully completed a number of pipeline testing service projects.

The financial and human resources modules of the MS10000 management system were successfully launched;

Xionggu's first welder vocational skills competition was a complete success;

The foundation stone of Xionggu Pipeline Installation and Pipeline Inspection Intelligent Robot Industrial Park was laid.

Obtain the support of key enterprises of national specialized, special and new "little giants".

As the main equipment, Xionggu welding machine helps the fourth line of the West-East Gas Pipeline, the middle section of the third line of the West-East Gas Pipeline, the Guhe Line, the Zhangzhou LNG project, the Fujian-Guangdong line, the Shandong pipeline network and other projects

Completed the research and development of A-305T narrow groove automatic argon arc external root welding system

Completed the research and development of A-806/40E flexible internal welding machine and successfully applied it to the project

Completed the research and development of DPS-500Pro new generation of all-digital multi-functional welding machine

Completed the research and development of DI series intelligent diameter detector and successfully applied it to the detection of complex mountain pipelines

Completed the research and development of a 3-channel independent system probe for magnetic flux leakage detector and successfully applied it to pipeline engineering detection

Passed the ISO27001 information security management system certification

Establishment of "Digital Operation Technology Center"

Complete the construction of the qualification system for R&D personnel

Won the "Hero per Mu" Class A enterprise in Sichuan Province

"A laser-based tracking technology" won the first prize of Sichuan Provincial Patent

Won the top 100 "Chengdu Industry Leading Enterprises".

Won the recognition of "Chengdu Municipal Industrial Design Center".

The MS10000 management system was successfully put into operation

The "Zhilian Welding" applet was successfully put into operation

A-802/20 and A-802/22 pipeline internal welding machines were successfully developed

MD-550 engine-driven welding machine was successfully developed

D7-500A new generation multi-functional welding machine was successfully developed

MI273 full-speed ultra-high-definition three-axis magnetic flux leakage internal detector was successfully applied to high-speed shale gas pipelines

MI168~MI323 series oil and gas field small pipe diameter testing equipment has been completed and engineering application has been realized

DI168~DI323 series deformation detector was successfully developed and applied in engineering

Xionggu welding machine assisted the Beijing-Shihan double-line project and the Mengxi coal-to-gas pipeline project

Xionggu welding machine helped Guangxi LNG export supporting Guilin branch line project

Xionggu welding machine assists the middle and southern sections of the natural gas pipeline project and the Beijing gas project

Xionggu Welding Machine helped the first National Pipe Network Maintenance and Repair Business Vocational Skills Competition

Started the QC team activities and successfully completed the first phase of the results release

Set up the manufacturing department control board amoeba

Won the first batch of "home-school-social enterprise" co-education practice bases

The company was awarded the national specialized and new "little giant" enterprise.

The company (Jiashi Electric) once again passed the national high-tech enterprise certification.

The company has passed the evaluation of the integration management system of industrialization and informatization.

The Xionggu pipeline automatic welding machine was successfully used for the in-service automatic welding and repair of the B-type sleeve of the West-East Gas Pipeline Line 3.

The company and the University of Electronic Science and Technology of China jointly set up a joint training practice base for graduate students.

The company's XG-A series automatic welding machine has fully entered Sinopec masonry construction enterprises to help the construction of the southern line of natural gas pipelines.

The full application of Xionggu XG-A series automatic welding machine by PetroChina Pipeline Bureau marks that Xionggu automatic welding has been fully recognized by PetroChina construction enterprises.

The company (oil and gas science and technology) was recognized as a national high-tech enterprise for the first time.

The company completed the research and development of φ168, φ219 and φ273 ultra-high-definition magnetic flux leakage internal detector prototypes.

The company completed the construction of φ168, φ219 and φ273 pulling and passing through the experimental pipelines.

The stress detection technology independently developed by the company has been tested on site.

The company passed the acceptance of the PLBS project of the Southwest Pipeline.

The company has carried out technical service projects such as internal testing data review, small pipe diameter magnetic leakage internal detection, stress testing, etc.

Xionggu established an artificial intelligence research institute.

The company's non-destructive testing business has obtained MFL/CG testing certificate.

Xionggu pipeline automatic welding machine was successfully used in marine pipeline engineering.

Xionggu Company obtained the evaluation certificate of the integration of industrialization and industrialization management system.

DingTalk intelligent office system was successfully launched.

Passed the certification of provincial technology enterprise technology center.

The automatic welding machine of Xionggu pipeline helps the northern section of the natural gas pipeline to be completed completely.

Xionggu A-305 Pipe Automatic Welder Shines in the 2019 International Competition.

Xionggu Company was awarded the Sichuan Provincial Integrity Demonstration Enterprise.

Xionggu Company was selected as a gazelle enterprise in Chengdu High-tech Zone in 2019.

Listed on the list of "Double Hundred Projects" of Chengdu's new economy in 2019.

Cooperate with Chengdu Technician College to establish a joint pipeline automatic welding training base.

Xionggu pipeline automatic welding machine went abroad and entered the construction in Thailand and Saudi Arabia.

The company has established a pipeline intelligent welding R&D center and a wide bandgap power semiconductor power supply R&D center.

The company has set up a whole network marketing department, launched the whole network marketing, traditional manufacturing enterprises + Internet, and opened the road of Internet transformation.

The Xionggu pipeline automatic welding machine helped the ninth bid section of the natural gas pipeline to take the lead in completing the welding of the main project.

The 2018 edition of Xionggu's corporate culture manual was officially published, and speech contests and team building activities were carried out around the main body of corporate culture for the second time, and employees' recognition of corporate culture was greatly improved.

The company started the management of the division of work system.

Participated in the China International Pipeline Conference, and the Xionggu pipe welding machine has been recognized by more users.

The company's sales performance reached a record high, with a sales output value of more than 200 million yuan.

MPS-500 pipeline multi-functional welding machine has become the competition machine of the five major pipeline operating companies of PetroChina, comprehensively replacing foreign brands, and becoming the main equipment for the maintenance and rescue of the five major pipeline companies.

Xionggu pipeline automatic welding machine entered a new industry other than oil and gas pipelines.

The "A-300X and A-610" developed by the company were identified as the first (set) of major technical equipment in Sichuan Province in 2016.

The company won the "Development of XG-A Series Pipeline Automatic Welding System" issued by the Sichuan Provincial Department of Science and Technology.

The company held the first dealer conference and achieved excellent results.

The company's automatic welding units have entered large-scale natural gas pipeline projects in large quantities.

The company participated in the Essen Welding and Cutting Exhibition in Germany, and successfully displayed a variety of intelligent long-distance pipeline welding equipment with independent intellectual property rights.

The company was awarded the "well-known enterprise in China's welding equipment industry".

The company hosted the "2017 China Engineering Construction Welding Forum".

The company held a 2017 strategic seminar to determine the company's vision and three-year goals.

XG-A series pipeline automatic welding system has passed the appraisal of scientific and technological achievements organized by China Petroleum Engineering Construction Association.

Mass production of Xionggu A-610 double-torch pipeline automatic external welding system.

The automatic welding system of Xionggu pipeline passed the -40°C low temperature welding test.

Xionggu automatic pipeline welding system has been put into batch application in domestic pipeline engineering.

Chengdu Xionggu Oil & Gas Technology Co., Ltd. was established.

General Manager Xiong Jian won the "Special Contribution Award of the Society" of the 21st National Welding Academic Conference.

Li Yizhong, the leader of the National Committee of the Chinese People's Political Consultative Conference, and his entourage visited Xionggu Company for investigation and guidance.

The welding experts of the natural gas company visited the company to inspect and certify Xionggu's pipeline welding equipment, and gave high praise to Xionggu's pipeline welding equipment.

Xionggu intelligent pipeline welding equipment A-808/48 internal welding machine was successfully developed, and signed a strategic cooperation agreement with Sichuan Oil Construction Co., Ltd. on automatic welding machine, which accelerated the localization process of automatic pipeline welding equipment.

Interview with the film crew of the "Chengdu Science and Technology Annual Conference" hosted by the Chengdu Municipal People's Government – Xionggu's scientific and technological innovation service platform, which was highly praised.

The company's technical service department won the honor of "Chengdu Model Worker Collective".

The company's largest amoeba inverter welding machine division was established, and with the further extension and refinement of amoeba operation, the layout of "overall efficiency optimization" was basically completed.

The intelligent pipeline welding equipment A-808/48 internal welding machine was successfully developed and highly recognized by oil pipeline construction enterprises.

The semi-automatic metal powder core root welding equipment DPS-500P and DSA-500 for pipeline have been successfully developed, providing world-class welding equipment for the root welding of pipeline steel above X80 level.

MPS-500 and D7-500 (N) multi-functional welding machines for pipe welding passed the energy-saving product certification, won the title of national energy-saving products, and were included in the 2014 national energy-saving procurement product catalog.

Participated in the international welding equipment exhibition held in Dubai and Tehran, and set up distributors abroad, laying the foundation for increasing the sales of the international pipe welding market. The company's A-208 gas tank intelligent welding equipment was exported to Vietnam and entered the Southeast Asian market.

Signed a strategic cooperation agreement with Sichuan Oil Construction Co., Ltd. on automatic welding machines, and accelerated the localization process of pipeline automatic welding equipment.

Launched the e-commerce marketing work, and used the Internet to build a bridge of direct communication with customers. Initial results have been achieved.

The company has won the honors of "Excellent High-tech Enterprise", "Most Socially Responsible Enterprise", "Chengdu Intellectual Property Pilot Enterprise", "Safety Production Standardization Level 3 Enterprise", "National High-tech Enterprise" and provincial and municipal famous brand products.

With the support of Sichuan Longjiang Sinology Academy, Kumagai Mingzhitang Children's Sinology Class was opened, which did a valuable thing for the healthy growth of employees' children.

A colorful Spring Festival party for the Year of the Horse was held, which promoted the spiritual and cultural life of employees and improved team cohesion.

Our company's A-300 intelligent pipeline full-position automatic welding machine has passed the acceptance of the "Sichuan Provincial Major Technical Equipment Innovation and Development Plan Project" of the Provincial and Municipal Economic and Information Commissions.

The company co-sponsored the 2013 annual meeting with the Welding Committee of the Provincial Mechanical Engineering Society, the Welding Committee of the Provincial Staff Technical Association, and Atlantic Welding Materials Co., Ltd. The participants visited our company and affirmed the achievements of our company in the development of new technologies such as automation and digitalization.

The Chinese culture reader "Xionggu on the Road" was published 4 issues this year, focusing on the four themes of "selection", "education", "use" and "retention" of talent training, comprehensively explaining and discussing, so that the company's talent concept of "morality first, education first" is deeply rooted in the hearts of the people.

Our company's technology center was named "Chengdu Enterprise Technology Center" by Chengdu Economic and Information Technology Commission, and issued a certificate and license.

The company was awarded the honorary title of "Excellent Enterprise of Open Factory Affairs and Democratic Management" issued by the Chengdu Municipal Party Committee and the Municipal Government.

The company held a strategic seminar in 2013 and established the strategic goal of achieving sales revenue of 300 million yuan within three years and becoming a domestic and global pipe welding system service expert. At the same time, specific strategies for multiple market segments were also clarified.

The company launched the action of "doing a good deed every day", established the "Xionggu Love Fund", implemented humanized systems such as dividends for all employees and the distribution of "filial piety money" to employees' parents, and co-organized the quarterly corporate culture reading magazine "Xionggu on the Road" with Sichuan Longjiang Sinology Academy.

Xionggu welding machine continues to be unanimously recognized by the domestic oil and gas pipeline construction industry, and has entered overseas markets such as Africa, the Middle East and Central Asia in batches.

The MD-2×400CC/CV digital pipe welding workstation product project was funded by the Sichuan Provincial Economic and Information Commission.

After the strict verification and review procedures of the French Bell Verification Group, our company has obtained the certificates of quality management system (ISO9001: 2008), environmental management system (ISO14001: 2004) and occupational safety and health management system (OHSAS18001: 2007) issued by the French Standards Association (AFNQ-AFNOR). The acquisition of the three-in-one international certification marks a new level of our company's modern enterprise management.

The project of "MPS Industrialization of Pipeline Semi-automatic Welding Equipment Based on IGBT Application" undertaken by our company was reviewed by the acceptance team composed of relevant leaders and experts of Sichuan Provincial Development and Reform Commission and Sichuan Provincial Economic and Information Commission, and passed the acceptance of production capacity in March 2011 and project acceptance in July, marking the upgrading of our company's scientific and technological innovation capabilities.

The MD-2×400CC/CV diesel-driven digital pipeline welding workstation of the Innovation Fund Project of the Ministry of Science and Technology undertaken by our company has passed the achievement appraisal organized by the Sichuan Provincial Department of Science and Technology at one time.

At the "Innovation and Strengthening" Welding International Forum held by the Chinese Mechanical Engineering Society and its Welding Branch, our company is guided by innovative technology, committed to the concept of "providing green industrial electrical products" and the fruitful results achieved in the field of long-distance pipeline welding, which has been highly praised.

A large number of Xionggu welding machines are used in the foreign sections of the China-Myanmar oil and gas pipeline, creating a situation in which Xionggu welding machines go abroad in large quantities. In 2011, our company has accounted for more than 70% of the new pipe welding equipment in China.

In 2011, at the 6th General Meeting of the Welding Technology Professional Committee of China Petroleum Engineering Construction Association, Mr. Xiong Jian, the general manager of our company, served as the vice chairman and was responsible for the work of welding equipment and materials.

In September 2011, our company successfully participated in the "7th China International Pipeline Exhibition" held in Beijing and won the "Excellent Enterprise Award". Our company has the ability to provide a full set of pipe welding equipment solutions, which can fully meet the requirements of the current new pipe welding process, and has become the preferred brand of domestic pipe welding equipment.

Xionggu Welding Machine participated in the 10th National Engineering Construction System Vocational Skills Competition held in Panjihua in April 2011, and made due contributions to the complete success of the competition.

The successful holding of the lecture on Chinese culture and the second training course on primary management ability have achieved good training results.

The company's corporate cultural activities such as the company's staff sports meeting, employee mountaineering festival, and employee red song meeting are active, and the company was recommended by the Chengdu Federation of Trade Unions to declare the 2011 "Chengdu Labor Relations Harmonious Enterprise".

The company's new base located in Chengdu High-tech Industrial Development Zone (West District), a state-level economic development zone, has been put into use, which has accelerated the company's modernization process.

The company introduces professional talents, sets up a human resources department, and establishes a complete modern enterprise human resources management system.

The company's 2010 staff sports meeting and tourism and cultural festival were successfully held in the company's new area and Xiling Snow Mountain Scenic Area.

The intermediate training course for the company's management personnel (Kumagai "Huangpu" Phase I) was completed, and the trainees were physically and mentally cultivated, and the management level of the enterprise was greatly improved.

The company's MD-2×400 welding machine has been supported by the Technology Innovation Fund of Science and Technology Enterprises of the Ministry of Science and Technology.

The company's energy-saving product MD-320CC/CV diesel-driven semi-automatic welding machine entered the market, leading the field of diesel self-driven welding machine.

The welding performance of the company's ACT-350 inverter digital AC/DC pulse argon arc welding machine has passed the expert appraisal of the Organizing Committee of the 10th National Engineering Construction System Vocational Skills Competition.

The company's A-300 automatic welding trolley was successfully applied to the construction of oil pipelines.

The company's inverter arc welding machine was awarded the title of "Sichuan Famous Brand" by the Sichuan Provincial People's Government. 10. The company's employee mountaineering festival was successfully held at the Great Wall of Jinlongshan in Chengdu.

The "I Grow Together with Xionggu " Employee Speech Contest was successfully held, and the company's corporate culture was deeply rooted in the hearts of the people.

For the first time since its establishment, the company has completed the systematic combing and adjustment of the corporate vision, mission, core values, etc., which has laid a solid foundation for the company's third reform.

The main project of the company's new factory located in Chengdu High-tech West Zone, a state-level economic development zone, was completed.

In the final of the welder of the 3rd National Vocational Skills Competition for Employees, our company's NB-350 semi-automatic welding machine was used for the competition.

Xionggu Jiashi MPS welding machine has been recognized by the Petroleum Pipeline Bureau, and has been listed as the preferred domestic procurement brand and has been used in batches.

The company was awarded the honorary title of "Advanced Unit of Labor Security" issued by the local government in 2009.

The company won the honorary titles of "Harmonious Labor Relations Enterprise" and "Worker Pioneer" by Chengdu Municipal Government and Chengdu Federation of Trade Unions.

The company applied for the National Development and Reform Commission's "Industrialization Project of Pipeline Semi-automatic Welding Equipment Based on IGBT Application" and passed the review and approval.

DSA-500 (P) inverter digital MIG/MAG semi-automatic welding machine has been successfully developed, which can meet the process requirements of metal powder core welding wire for X80 steel in China's West-East Gas Transmission Line.

The company's NB-350 and WS5-400 welding machines were designated as special welding machines by the China Engineering Construction System Welding Competition; NB-500 was designated as a special welding machine by the Sichuan Division of the National Technical School Welding Competition.

The working meeting of the China Shipbuilding Industry Efficient Welding Technology Guidance Group undertaken by the company was held in Chengdu.

After the assessment and evaluation of our company's product MPS-500 last year, Sinopec Sichuan-East Gas Transmission National Key Project has purchased Kumagai welding machines in large quantities this year, and MPS-500 welding machines have become the main welding machines of the project.

The company's MPS-500 long-distance pipeline welding machine has been inspected and affirmed by the PetroChina Pipeline Bureau, and has entered the first, second, third and fourth companies of the Pipeline Bureau.

The company's products are exported to Algeria and other African countries and India in South Asia in large quantities, and the influence of Kumagai Company is expanding day by day.

The company's party, government and industry jointly held a charity activity of "paying attention to the disadvantaged and building harmony together", and donated more than 100 pieces of brand-new cold-proof clothing to the students of Puxigou Qiangzhai Primary School in Li County, Aba Prefecture, which is located deep in the mountains of the Kham Plateau, and the local response was strong.

The company's 3rd Staff Sports Meeting and the 11th Staff Tourism and Culture Festival were successfully held in the company's park and the Red Leaves Scenic Area of Penggou Snow Mountain in Miyarobi, which not only cultivated the sentiment of employees, but also reflected the harmonious and upward corporate culture of Kumagaya.

In the final of the 2nd National Staff Vocational Skills Competition for welders, our company's NB series CO2 semi-automatic welding machine is the machine used in the competition.

In the "Kumagai Cup" Technology Star Contest held by Changhang Group, Kumagai Welding Machine was used as a special welding machine for the competition.

DSA-500 inverter digital MIG/MAG semi-automatic welding machine won the special support of key science and technology projects in Qingyang District, Chengdu; MG series gasoline-driven multi-functional welding machine won the patent transformation funding project of Qingyang District, Chengdu.

In the key pipeline project of Sinopec Sichuan-to-East Gas Transmission, our company's MPS flux core self-protection semi-automatic welding machine was selected as the special welding machine for process evaluation and online welder qualification examination.

The digital multi-functional welding machine was successfully developed, and the company's products fully entered the digitalization.

The company obtained the approval of "National Encouraged Industrial Project Enterprise" by Sichuan Provincial Economic Commission (Chuanjing Industry Letter [2005] No. 99), and enjoyed the preferential policy of "Western Development".

The upgraded product of the D7 series welding machine, the MPS series pipe semi-automatic welding machine, was launched.

Entered Jiaolong Industrial Port, High-tech Development Zone, Qingyang District, Chengdu, and won the title of "Chengdu High-tech Enterprise".

In the final of the first National Staff Vocational Skills Competition for welders, our company's ZX7-400ST welding machine was designated as the competition machine.

The D7 series of semi-automatic pipeline welding machine has been successfully developed, which has filled the domestic gap and replaced imported products, and has been funded by the Innovation Fund of the Ministry of Science and Technology of the People's Republic of China and the title of national key new product.

Changed to Chengdu Xionggu Jiashi Electric Appliance Industry Co., Ltd., and took the lead in the petroleum industry to launch the NB-500A oil and gas pipeline welding special semi-automatic welding machine.

Through restructuring, Chengdu Xionggu Electric Welding Machine Factory, a joint-stock cooperative enterprise, was established.

The predecessor of Xionggu Company, Chengdu Western Electric Welding Machine Factory, was established.

By clicking 'Agree All', you agree to the storage of cookies on your device to enhance sitenavigation, analyze site usage and assist with our marketing efforts.