Product introduction

-

-

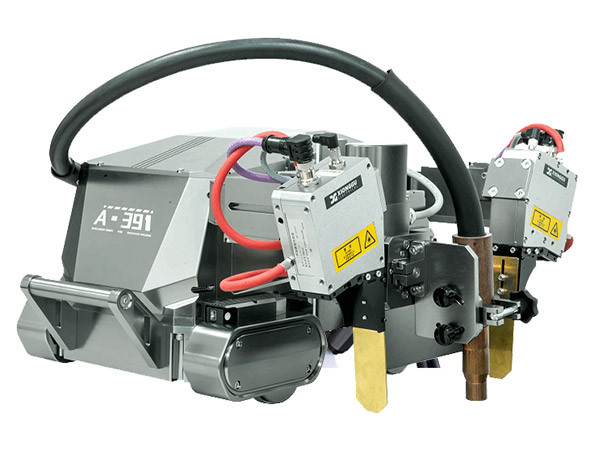

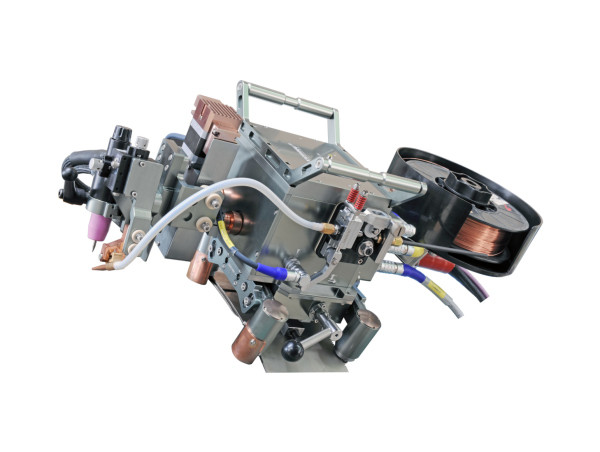

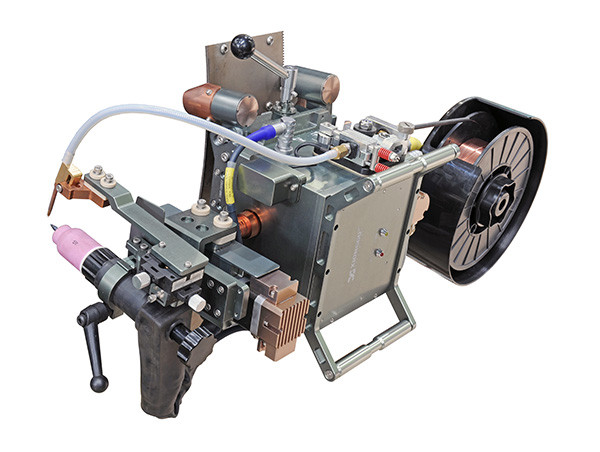

A-302 All Position Automatic Welding Workstation for Pipeline Maintenance and Repair

Function:It can be used for root pass, hot pass, fill & capping welding of pipeline. GMAW and FCAW-GS welding processes can be applied. All position welding of various workpieces can be realized if various tracks are applied.

Configuration:Welding head, LCD portable panel, digital welding power source, control cables, flexible magnet track, integrated workstation.

Product characteristics

◆Operated via LCD portable panel with display available in Chinese/English, convenient and intuitive.

◆Built-in welding expert database, corresponding welding parameters can be modified and called according to the access level, smooth transition of welding parameters in each layer and accurate all position welding can be realized.

◆Designed with welding seam arc tracking in vertical axis to reduce welder’s labor strength.

◆Weld bead image acquisition, display and storage, visual observation of weld bead forming.

◆4G mobile web, WIFI and QR code scanning interfaces are reserved; it can provide remote technical services and data cloud transmission to facilitate real-time quality management.

◆Wide range of inclination angle and torch vertical movement is suitable for pipeline emergency repair welding and butt welding.

◆The whole equipment integration workstation facilitates the transportation and management of pipeline maintenance and emergency repair equipment.

◆By changing different tracks, it can conduct all position welding of pipe of diameter larger than 168 mm and workpieces of curved surface and flat surface.

Product parameter

| Model | A-302 |

| Applicable Pipe Diameter | ≥Φ168 mm |

| Travel Speed | 0.1~1.5 m/min |

| Wire Feeding Speed | 2.5~16 m/min |

|

Number of Section perGroup |

1~180 Sections |

| Torch Oscillation Mode | Linear/pendular |

| Torch Vertical Movement | 0~80 mm |

| Torch Horizontal Movement | 0~50.8mm |

| Torch Horizontal Movement(manual) | 0~165 mm |

| Torch Inclination Angle | ±45° |

| Weight of Wire Spool | 5kg |

| Ambient Temperature | -40~55℃ |

| Altitude | 4500m |

| Ingress Protection | IP54 |

| Weight | 17kg |

| Weight | 725kg |

| Dimensions(L×W×H) | 350mm×600mm×350mm |

| Dimensions(L×W×H) | 950mm×1905mm×1422mm |