上一张

下一张

Function:

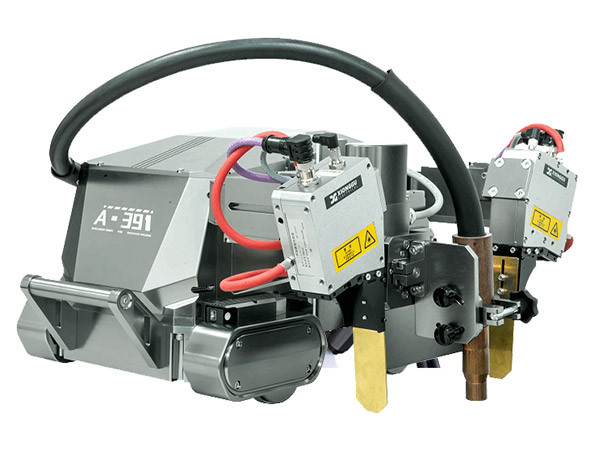

It can be used for all position welding of water pipelines, thermal pipelines, pressure steel pipes for storage power station, and large tank components, applicable for both GMAW/FCAW-GS welding processes. It meets requirement of automatic welding of various bevel designs.

Configuration:

Welding robot, external wire feeder, welding torch, portable panel, control cable, welding power source.

◆The welding robot adopts a magnetic suction chassis free of travel band and high efficiency. Applicable for all position welding of large-diameter steel pipes above Ф800.

◆Integrating laser vision sensing technology and arc sensing technology, autonomously identifying welds and completing welding parameter planning and welding navigation, reducing labor costs.

◆Configure wireless portable panel with IP68 protection level and graphical operation interface in both Chinese and English.

◆Equipped with a push-pull wire feeding system, with a welding torch length of 8.5 meters, the wire feeding is more stable.

◆Configure a pendulum oscillation mechanism to achieve butt weld and fillet weld welding.

◆Matched with the new generation welding power source DPS-500Pro, achieving more precise arc control. The welding machine integrates a robot controller internally, eliminating the need for additional robot control cabinets.

◆The system adopts an industrial Ethernet bus design, with high real-time communication and network interfaces such as 4G/5G and WIFI. It can connect to remote data management systems and has OTA online upgrade function.

| Model | A-391 |

| Product ID | 4364000001 |

| Applicable Pipe Diameter | ≥Φ800mm |

| Travel Speed | 0.1~1.5 m/min |

| Wire Feeding Speed | 2.5~15 m/min |

| Number of Section per Group | 1~180 Sections |

| Torch Oscillation Width | 0~40 mm |

| Torch Oscillation Mode | Linear/pendulum |

| Weight of Wire Spool | 5kg/15kg |

| Ambient Temperature | -20~55℃ |

| Altitude | ≤1000m(Duty circle will decrease when altitude is above 1000m) |

| Ingress Protection | IP54 |

| Weight | 26kg |

| Dimensions (L×W×H) | 520mm×480mm×252mm |

With continuous technological advancements, the appearance, color, and parameters may change. The parameters are for reference only and are not to be used as acceptance inspection standards.

By clicking 'Agree All', you agree to the storage of cookies on your device to enhance sitenavigation, analyze site usage and assist with our marketing efforts.