上一张

下一张

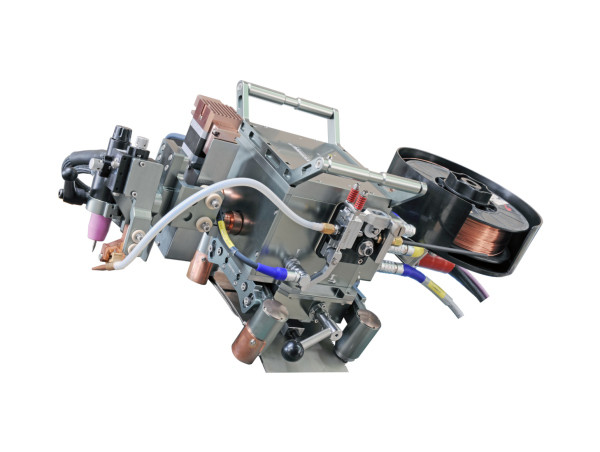

Function:

It can be used for root pass, hot pass, filling and capping welding of pipe joint by using GTAW welding process. All position welding of other workpiece can be realized if various tracks are installed.

Configuration:

Welding head, LCD portable panel, control cables, digital welding power source (Built in controller)

◆Operated by LCD portable panel with Chinese/English/Russian language interface, friendly and intuitive.

◆The system is operated via portable panel to reduce welder’s labor strength.

◆It is designed with built-in welding expert database, available to call corresponding welding parameters according to access level.

◆Parameters can be called via portable panel to realize smooth transition of welding parameters of each pass and precise all position welding.

◆Interfaces of 4G, WIFI and QR code scanning are reserved, it can provide remote technical services and data transmission in the cloud to realize convenient real time quality control.

◆It has the function of automatic arc tracking to comprehensively reduce the labor intensity of welders It is suitable for the welding of pipe diameters of 168mm and above if various tracks are installed.

| Model | A-305T |

| Applicable Pipe Diameter | ≥Φ76mm |

| Travel Speed | 0.1~1.5 m/min |

| Wire Feeding Speed | 2.5~16 m/min |

| Number of Section per Group | 1~180 Sections |

| Torch Oscillation Width | 0~50.8mm |

| Torch vertical movement | 0~50.8mm |

| Torch oscillation | Linear |

| Weight of Wire Spool | 5kg |

| Ambient Temperature | -40~55℃ |

| Altitude | 4500m |

| IP Rating | IP54 |

| Weight | 15kg |

| Dimensions (L×W×H) | 600mm×350mm×250mm |

With continuous technological advancements, the appearance, color, and parameters may change. The parameters are for reference only and are not to be used as acceptance inspection standards.

By clicking 'Agree All', you agree to the storage of cookies on your device to enhance sitenavigation, analyze site usage and assist with our marketing efforts.